Britech Industries – Rubber Stoppers

A fundamental part of scientific experimentation and laboratory work is using rubber stoppers that are small accessories used to plug holes, seal containers, serve as insulation, and offer protection. Though laboratory rubber stoppers are identified with laboratory and scientific use, they are found in a variety of applications due to their durability, strength, and ability to form a solid tight secure seal.

A fundamental part of scientific experimentation and laboratory work is using rubber stoppers that are small accessories used to plug holes, seal containers, serve as insulation, and offer protection. Though laboratory rubber stoppers are identified with laboratory and scientific use, they are found in a variety of applications due to their durability, strength, and ability to form a solid tight secure seal.

Using the highest quality rubber materials, Britech Industries produces the highest quality laboratory rubber stoppers designed and produced to meet the ever-growing demands of laboratory environments. One of the main considerations in conditions where chemicals are present is safety and the protection of workers. At the top of the list of measures taken to ensure the safety of workers is rubber stoppers that tightly seal flasks, tubes, and containers to keep liquids, gases, and chemicals contained regardless of how the container is handled.

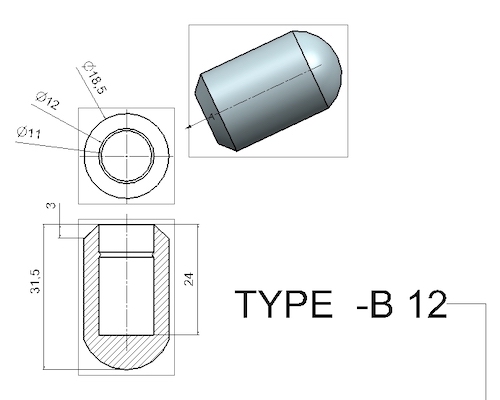

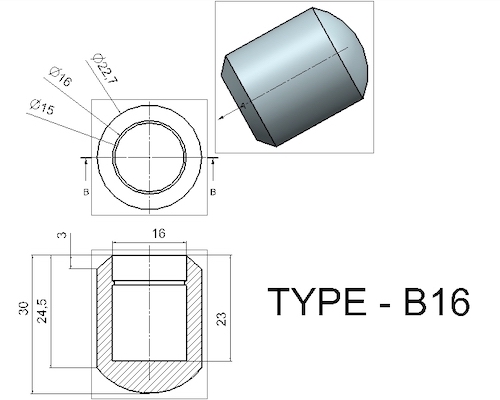

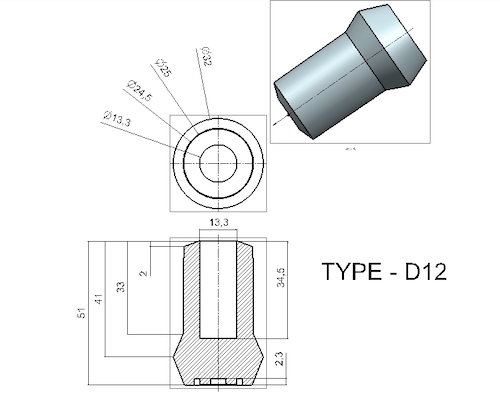

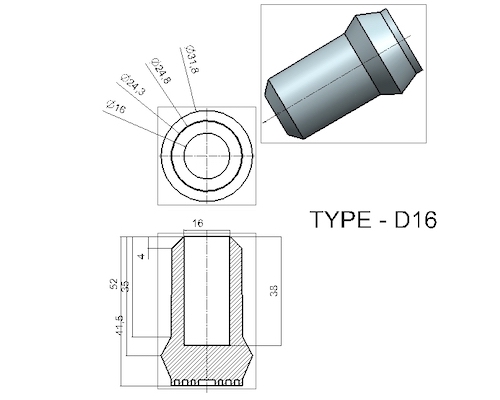

Rubber tips are a standard part of all crutches, whether the crutch is underarm or forearm. In most cases, crutches are a short-term solution to help patients walk after having had some form of leg injury and must be sturdy and strong enough to offer support and stability. Walking with crutches requires twice the energy required to walk normally, which necessitates rubber tips capable of withstanding the weight and motion.

Rubber tips are a standard part of all crutches, whether the crutch is underarm or forearm. In most cases, crutches are a short-term solution to help patients walk after having had some form of leg injury and must be sturdy and strong enough to offer support and stability. Walking with crutches requires twice the energy required to walk normally, which necessitates rubber tips capable of withstanding the weight and motion.

As an added feature, Britech Industries offers rubber tips in black, white, or grey, depending on the requirements of the crutch manufacturer. The different colors make it possible to perfectly match the tip to the design of the crutch.

As an added feature, Britech Industries offers rubber tips in black, white, or grey, depending on the requirements of the crutch manufacturer. The different colors make it possible to perfectly match the tip to the design of the crutch.