Rubber Molding

Rubber Molding Parts

Rubber molded parts are an important yet often overlooked facet of many industries, and Britech’s extensive catalog of products has been built to meet all of these challenging demands. The bulk of our rubber molded parts for sale are manufactured using high-quality and resilient SBR-60 rubber and other leading materials like neoprene, silicone, and natural rubber. Browse our entire collection of rubber molded parts for sale below, or contact us with questions about projects that require a more customized rubber molded part.

Rubber Molding Products for Sale

Rubber Grommets

Rubber grommets are available in various compounds, sizes, and shapes to meet specific needs. We can modify stock grommets in-house to save customers on tooling costs, custom manufacture grommets, and quick-ship in-stock products.

Rubber Bumpers

Our rubber bumper designs include rounded top bumpers, doughnut top bumpers, flat top bumpers, and large rubber dock bumpers for marine applications. Choose from a variety of bore diameters, recess depths, and outside diameters, or order custom rubber bumpers.

Rubber Washers

We produce competitively priced rubber washers using our in-house lathe cutting capabilities that provide exceptional precision on both outer and inner diameters. Our Fabrication & Prototype department can produce an unlimited variety of washers to meet all specifications.

Rubber Laboratory Stoppers

Rubber laboratory stoppers are widely used throughout scientific sectors and must reliably seal containers that can sometimes contain volatile chemicals or solvents. Using only the highest quality 40-durometer natural rubber, Britech can manufacture rubber stoppers to fit any hole.

Rubber Tips

Rubber tips, also known as rubber crutch and cane tips, or non-slip tips, provide a secure, tight fit with exceptional support and cushioning. This added traction, friction, and grip prevent slippage or unwanted movement that could lead to falls or accidents.

Rubber Caps

We manufacture all rubber caps from durable, chemical-resistant rubber that can withstand the particular chemicals or solvents present in the end applications. Our caps are routinely used in automotive production and certain aerospace applications.

Rubber Suction Cups

Our engineers and designers have configured a set of rubber suction cups that meet industry standards for performance, capacity, and design. Browse our available rubber suction cup products or reach out to us with more details on a custom project.

Custom Rubber Molding

In addition to our standardized rubber products, we offer customers access to custom rubber molding services that involve particular rubber materials, unique dimensions, challenging shapes, or a need to meet certain performance requirements.

Types of Rubber Molding

Britech Industries uses modernized rubber molding equipment and processes to ensure premium-quality products that adhere to stringent design specifications and performance expectations while remaining competitively priced with fast shipping times.

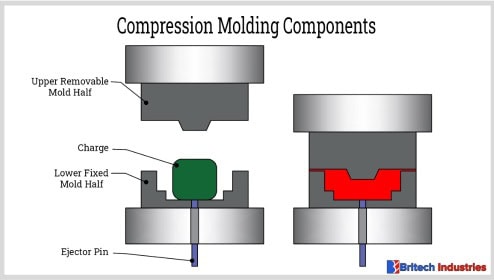

Rubber Compression Molding

Compression molding is similar to making a waffle in a waffle iron. The process was initially used to form plastics and has been adapted for rubber applications. It is a highly efficient and economical production method that produces excellent quality parts that have the same specifications throughout a run. A predetermined amount of rubber compound is placed directly into the mold cavity. It is compressed into the shape of the cavity by closing the two sides of the mold. Pressure is maintained, and heat is added to cure the product. Once the mold cools and the product is cured, it is removed from the mold. Any excess rubber, referred to as flash, is removed and set aside for reuse.

Rubber Injection Molding

Rubber injection molding uses tremendous pressure and heat to take a strip of raw rubber and force it through a nozzle and into the cavities or parts of a mold and subsequently cures the rubber into its final shape or shapes. Injection molding rubber is suitable for high-volume production projects and can match intricate shapes with exceptional precision and speed. It is a cost-effective solution for seals and gaskets, producing a large quantity of individual pieces in a single cycle. Parts have minimal wasted material as each shot is carefully calibrated to only fill the mold with limited flashing to remove after leaving the injection press.

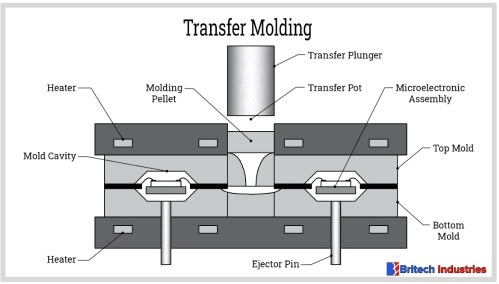

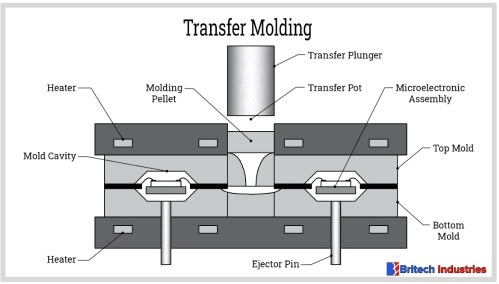

Rubber Transfer Molding

Transfer molding begins with a piece of uncured rubber preformed to a specified weight and shape. It is placed in a portion of a mold called the “pot”, which is located between the top plate of the mold and the ram, and closed to transfer the uncured rubber into the mold cavity through a runner and gate system. The uncured rubber is held under pressure and temperature to activate the curing process. The cured part is ejected after a specified period. Regardless of the process used, parts and components produced from rubber molding have strength, endurance, flexibility, stress and wear resistance, and are recyclable. They can be efficiently mass-produced using a wide variety of designs.

Advantages of Rubber Molding

Working with Britech Industries for rubber molding parts provides several advantages over international companies or other domestic manufacturers with less experience working with unique or complex designs.

Materials Used in Rubber Molding

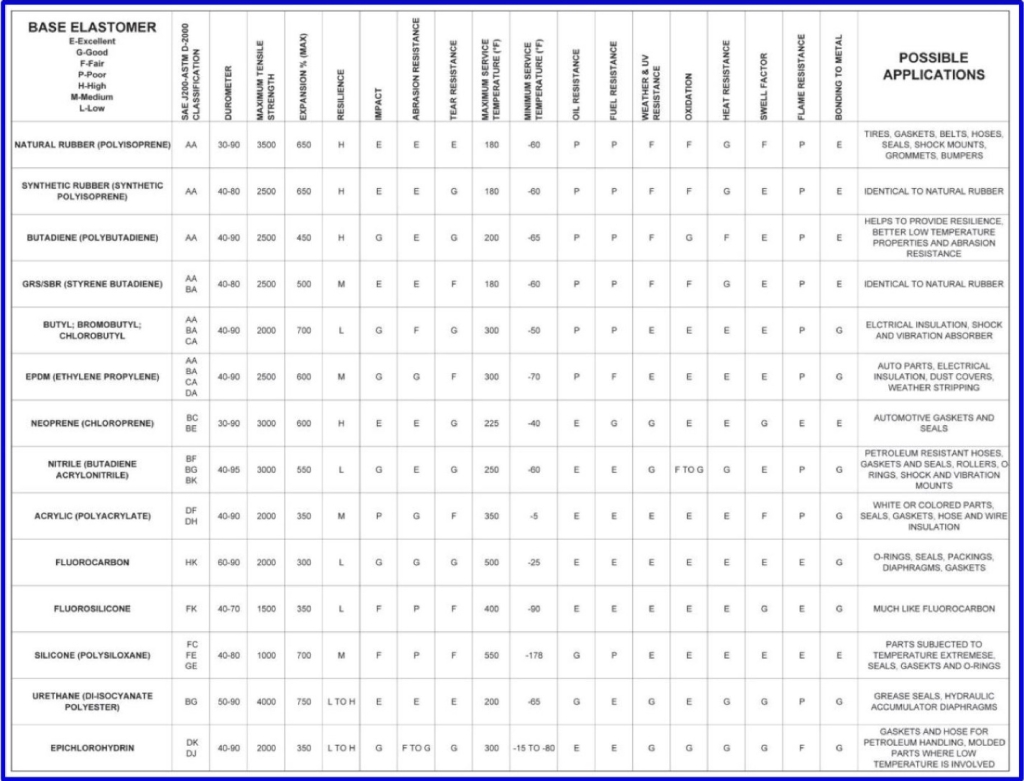

Base Elastomers & Suitability Rankings

Britech Industries excels at providing additional resources and support for customers unsure of the right rubber material to use for their end applications. Deciding on the right rubber elastomer to use can make all the difference when it comes to performance, reliability, and longevity. For example, natural rubber offers exceptional impact and abrasion resistance but has a poor resistance to fuels or solvents. On the other hand, urethane rubber offers the same level of impact performance but can also withstand exposure to fuel and solvents. As long as you have the details regarding the end application of your part design, our experienced and knowledgeable team can find the perfect rubber for your use.

Contact Us

Contact us today for quotes or more information on our custom rubber and plastic extrusion or molding solutions designed to meet your specifications!

"*" indicates required fields